Binder dosage

Find out more about the outstanding features and advantages of KLANN binder dosing systems:

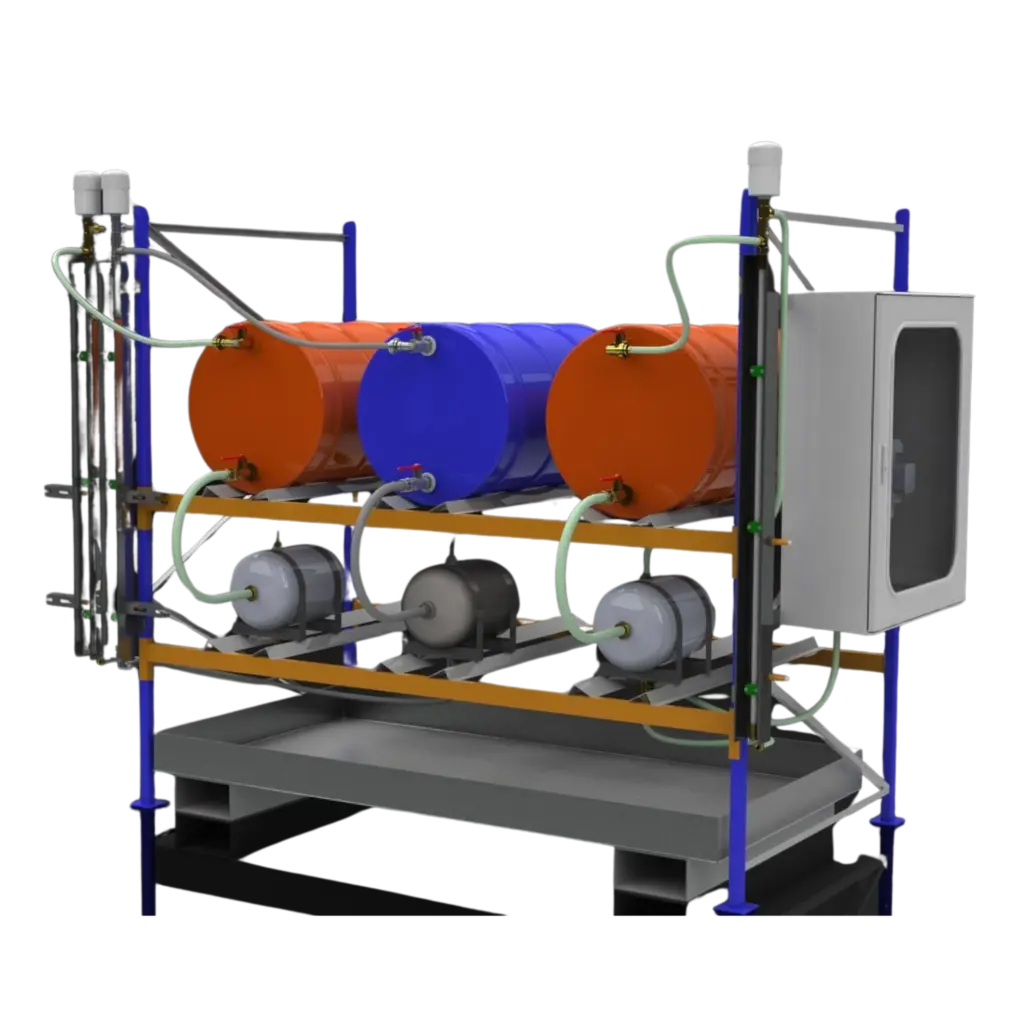

The binder dosing stations from KLANN offer optical monitoring of the binder quality through the use of glass cylinders. This enables precise dosing, which is ensured by adapted dosing pump sizes.

Another innovation is the visibility of air bubbles in the binder in the event of a defective pipe connection from the binder storage. This enables problems to be quickly identified and resolved.

The storage containers enable an efficient supply of binder even from long distances. In addition, the binder nozzles on the mixer can be easily removed, which makes cleaning and calibration operations easier.

By using position measuring systems on the dosing system, the binder quantities can be easily adjusted. The clear integration into the control cabinet with an integrated drip tray for leaks ensures a safe and orderly installation.

Our binder dosing systems are designed to meet your requirements, even when handling corrosive binders. Rely on KLANN systems technology for advanced solutions that ensure the highest precision and safety.

- Visual monitoring of binder quality through the use of glass cylinders.

- Accurate dosing thanks to adapted dosing pump sizes

- Visibility of air bubbles in the binder if the pipe connection from the binder storage is defective

- Storage container for binder supply from a long distance

- Easily removable binder nozzles on the mixer for cleaning and calibration applications

- Easy adjustment of the binder quantities through the use of distance measuring systems on the dosing system

- Clear installation in a control cabinet with an integrated drip tray for leaks

- Required execution even with corrosive binders