Core shooting machines

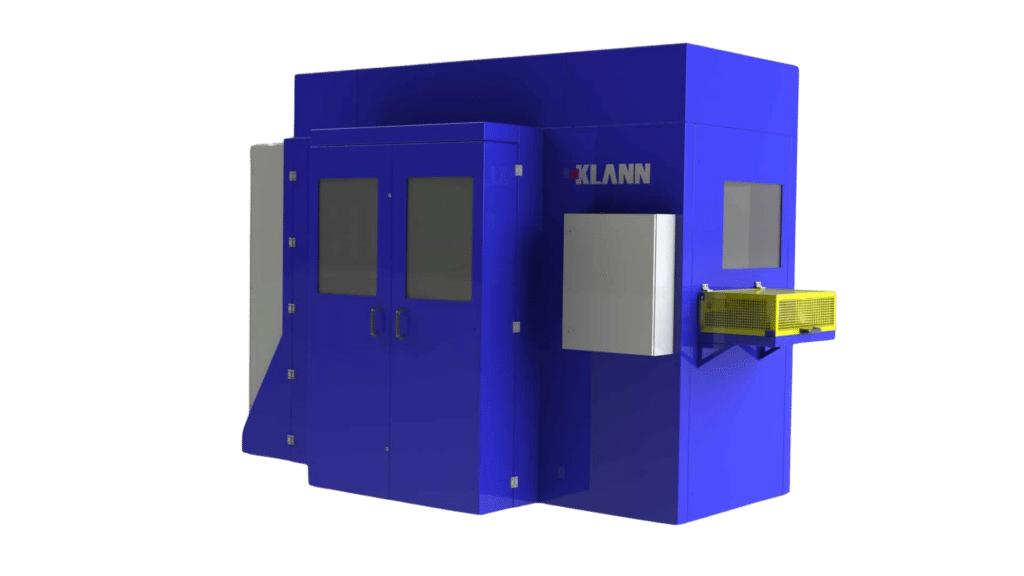

KLANN Anlagentechnik is a leading provider of state-of-the-art core shooting machines designed for a variety of core manufacturing processes, including cold and hot box, CO₂ and croning processes. Our proven systems have proven to be extremely reliable in a variety of applications over an impressive period of more than two decades and are available in various shooting volume variants from 1 to 60 liters.

Our comprehensive offering extends far beyond individual machines and includes complete systems that cover all aspects of core production. From quartz sand delivery to processing, metered addition of binders in core sand mixers to automated core handling, we offer complete solutions in the form of highly developed, fully automated core production centers. Trust in the proven quality and reliability of KLANN Anlagentechnik to optimally meet your specific requirements for advanced core manufacturing technologies.

The KLANN core shooting machines are characterized by:

- High, reproducible core quality through delivery of complete systems including sand processing and conveying

- Short cycle times through optimized design and process flows and therefore high hourly output

- High availability with long maintenance intervals

- Small, compact design with a small footprint

- Good accessibility for tool changes and maintenance purposes

The following versions of core shooting machines are available

All core shooting machines listed can also be offered as core production centers with integrated sand processing.

Core shooting machines with belt discharge, so-called belt automatics, are among the most productive core shooting machines. They are primarily used in large-scale production in the valves, fittings and automotive industries. By fully automatically placing the manufactured cores on a conveyor belt, production can be highly automated. It is no longer necessary for the operator to remove the cores from the machine table and then restart the machine. The machine always runs at maximum productivity and the cores can be picked up by untrained personnel. Because the cores are buffered on the belt, the cores can cure for longer before being picked up manually or by a robotic system. The automatic placement of cores on a conveyor belt minimizes operator intervention, allowing one person to operate multiple machines.

In addition to pure hot boxes, cold boxes, Croning, Betaset or CO₂ machines, combination machines are also possible that can be converted to the other process after a tool change.

The special shooting valve with high shooting impulse ensures a tight core and allows fine shooting channels.

During the curing process, the shooting head moves out of the core box area to avoid hardening of the core sand in the shooting head and in the shooting nozzles. The automatic tilting head adjustment adapts effortlessly to different core box thicknesses.

The stable base frame not only ensures a torsion-resistant construction of the machine even under high clamping forces, but also includes cleaning drawers for effortless care.

In addition, the system offers the option of a core handling robot for smooth further processing or storage of the cores.

Further special features of the KLANN belt machines are:

- Mandrel pulling device to insert vertical saving mandrels into the core box

- Lateral loose part pulling device

- Core box changing aid

- Automatic tilting head adjustment

- Blow-off and release agent spray devices

- Automatic deburring device

- Base frame with cleaning drawers

- Core handling robot for further processing

Technical data for belt machines

| unity | P5 BA HB | P8 BA HB | P15 BA HB | |

|---|---|---|---|---|

| Shooting volume | dm³ | 5 | 8 | 15 |

| Sand supply – loading | dm³ | 60 | 60 | 120 |

| Shooting pressure, adjustable | bar | 1 - 6 | 1 - 6 | 1 - 6 |

| Compressed air consumption per cycle | dm³ | 25 | 32 | 60 |

| Cycle times, without heating, mandrel drawing device. Blow | Knot. | 5 | 7 | 9 |

| Core box dimensions | ||||

| minimum thickness per half | mm | 40 | 40 | 70 |

| maximum thickness per half | mm | 110 | 110 | 150 |

| maximum length | mm | 500 | 600 | 800 |

| maximum height | mm | 250 | 300 | 400 |

| Stroke of the clamping device | mm | 320 | 320 | 450 |

| Machine dimensions | ||||

| Height [H] | mm | 2.400 | 2.650 | 2.800 |

| Width [B] | mm | 1.800 | 1.800 | 2.200 |

| Length [L] | mm | 4.650 | 4.650 | 4.900 |

| Bandwidth [Y] | mm | 500 | 600 | 800 |

| Belt height [X] | mm | 700 - 1.000 | 700 - 1.000 | 700 - 1.000 |

| Belt length [l] | mm | 1.850 | 2.100 | 2.100 |

The standard KLANN core shooting machines with machine table discharge of the produced cores are characterized by short cycle times and high reliability, which enables optimal productivity in core production.

Thanks to an optimized design with a small footprint, installation in confined spaces and without a foundation recess is also possible.

Compared to competing machines, the KLANN core shooting machines with machine table discharge have many design advantages. For example, when gassing the core box, the shooting head is moved out of the gassing area in order to prevent the core sand from hardening in the shooting openings.

The machine table discharge is firmly connected to the machine table, so that the core box can be moved out of the machine at any height, which saves cycle time.

In addition to pure hot boxes, cold boxes, Croning, Betaset or CO₂ machines for horizontal or vertical split core boxes, combination machines are also possible that can be converted to the other process after a tool change.

Our groundbreaking technology presents a firing valve with impressive firing momentum that is characterized by exceptional efficiency. During the gassing process, the shooting head moves precisely, accompanied by a lateral loose part pulling device and a sophisticated core can changing aid. The automatic tilting head adjustment adapts effortlessly to different core box widths.

The stable base frame not only ensures a torsion-resistant construction that does not give in even under high clamping forces, but also includes cleaning drawers for effortless care. In addition, the system offers the option of a core handling robot for smooth further processing or storage of the cores.

Design details of the KLANN core shooting machines with machine table discharge:

- Special firing valve to achieve a high firing impulse

- The shooting head is moved sideways during the gassing process

- Clamping jaw height adjustment to always clamp the core boxes in the middle

- Core box changing aid

- Base frame with cleaning drawers

- Core handling robots for further processing or storage

Technical data table pusher machines

| unity | P5-CB/CO2-VA | P12-CB/CO2-VA | P25-CB/CO2-VA | P40-CB/CO2-VA | |

|---|---|---|---|---|---|

| Shooting volume | dm³ | 5 | 8 | 15 | 40 |

| Sand supply – loading | dm³ | 60 | 60 | 120 | 250 |

| Shooting pressure, adjustable | bar | 1 - 6 | 1 - 6 | 1 - 6 | 1 - 6 |

| Compressed air consumption per cycle | dm³ | 20 | 20 | 50 | 80 |

| Cycle times, without heating, mandrel drawing device. Blow | Knot. | 12 | 12 | 16 | 20 |

| Tension paths | |||||

| Machine table - shooting head | mm | 550 - 190 | 550 - 190 | 715 - 295 | 750 - 250 |

| between clamping jaws | mm | 510 - 110 | 510 - 110 | 740 - 180 | 880 - 250 |

| pressing forces | |||||

| Jaws | N | 13.000 | 23.500 | 37.000 | 60.000 |

| machine table | N | 23.500 | 50.000 | 94.000 | 150.000 |

| Machine dimensions | |||||

| Height [H] | mm | 2.500 | 2.800 | 3.150 | 3.500 |

| Width [B] | mm | 2.850 | 3.350 | 3.650 | 4.000 |

| Depth [T] | mm | 1.560 | 1.560 | 1.850 | 2.500 |

| Machine table front [t] | mm | 350 | 350 | 550 | 950 |

In addition to the well-known conveyor belt machines and machine table discharge machines, KLANN Anlagentechnik also offers tailor-made solutions according to individual customer requirements. Our product range includes, for example, state-of-the-art hot box core shooting machines that are designed for horizontally divided core boxes with drawer discharge. These machines are characterized by outstanding productivity with minimal core box wear. With KLANN you receive tailor-made solutions that are tailored to the specific needs of your application.

Our other special machines include rotary transfer machines and core shooting machines with integrated core assembly machines. These advanced technologies not only offer high efficiency, but also precise and automated core production. Rely on KLANN Anlagentechnik for industry-leading machine solutions that meet the individual needs of your company.

An advantage over competitive machines is based on the special shooting valve with an impressive firing impulse, which is characterized by exceptional efficiency.

Another advantage is that during the curing process, the shooting head moves away from the area of the hot core box in order to avoid hardening of the core sand in the shooting head or the shooting openings.

The hot box core shooting machine for horizontally divided core boxes shown in the animation has the following special features:

- Core box preheating station

- Travel rails for easy removal of the hot core box

- Travel rails for cleaning the box and the sieve inserts

- Lateral loose part pulling device

- Possibility of driving the entire sand cart out of the machine.

- Aluminum shooting cylinder for easier handling

- Base frame with cleaning drawers

- Core handling robots for further processing or storage

Technical data for special core shooting machines

| unity | P5-CB CO2 VA | P12-CB CO2 VA | P25-CB CO2 VA |

|

|---|---|---|---|---|

| Shooting volume | dm³ | 5 | 8 | 15 |

| Sand supply – loading | dm³ | 60 | 60 | 120 |

| Shooting pressure, adjustable | bar | 1 - 6 | 1 - 6 | 1 - 6 |

| Compressed air consumption per cycle | dm³ | 20 | 20 | 50 |

| Cycle times, without heating, mandrel drawing device. Blow | Knot. | 12 | 12 | 16 |

| Tension paths | ||||

| Machine table - shooting head | mm | 550 - 190 | 550 - 190 | 715 - 295 |

| between clamping jaws | mm | 510 - 110 | 510 - 110 | 740 - 180 |

| pressing forces | ||||

| Jaws | N | 13.000 | 23.500 | 37.000 |

| machine table | N | 23.500 | 50.000 | 94.000 |

| Machine dimensions |