Fluidized bed systems are used for a wide variety of applications in bulk solids technology. With these systems, KLANN has gained experience from foundry technology, where low-quality quartz sands are cleaned of fine dust components using fluidized bed dedusters for the production of core sands. Low-dust quartz sand reduces the use of binders in the production of core sands, as well as molding sands, as the total sand grain surface to be wetted is reduced. Another advantage is that better gassing is achieved in the later sand core during casting due to the spherical packing of the sand grains.

KLANN offers batch fluidized bed classifiers for various applications:

- Dust gathering of bulk goods

- Cooling or heating of bulk materials

- Separation of light fractions

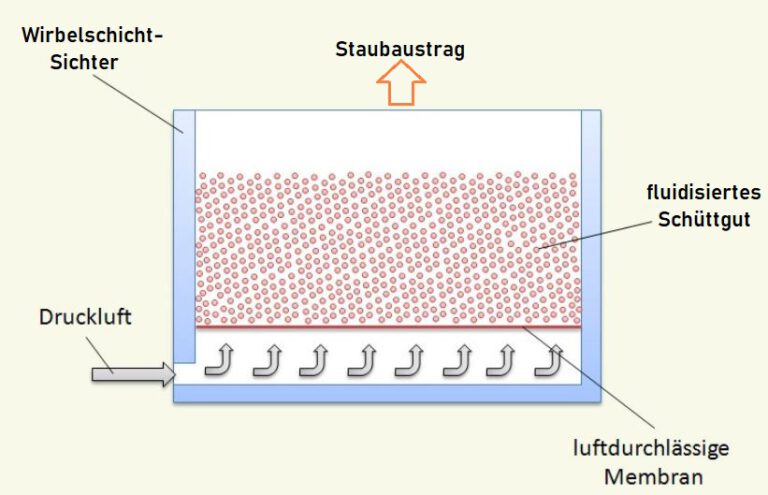

When compressed air flows into a sieve base (membrane), the bulk material above it is fluidized and set in motion. Depending on the flow speed, lighter material can be discharged or only uniform heating or cooling can occur. The material is introduced through the lid from above, and the treated material is discharged from the middle downwards with an open closure via rotary flaps.